What is the temperature tolerance of UCP bearings?

The temperature tolerance of UCP bearings, also known as pillow block bearings, can vary depending on several factors, including the bearing materials, lubrication, and seal design. Here’s a detailed explanation of the temperature tolerance of UCP bearings:

1. Bearing Materials: The materials used in the construction of UCP bearings play a significant role in determining their temperature tolerance. Common materials for UCP bearings include chrome steel, stainless steel, and cast iron. Chrome steel bearings typically have a higher temperature tolerance compared to stainless steel or cast iron bearings. Specialty materials such as heat-resistant alloys or ceramics may be used for UCP bearings intended for extremely high-temperature applications.

2. Lubrication: Proper lubrication is crucial for maintaining the temperature tolerance of UCP bearings. Lubricants help reduce friction, dissipate heat, and protect bearing surfaces. The choice of lubricant depends on the operating temperature range. Standard greases and oils are suitable for moderate temperature applications. For higher temperatures, synthetic lubricants or specialty high-temperature greases may be recommended to ensure adequate lubrication and thermal stability.

3. Seal Design: The seal design of UCP bearings can affect their temperature tolerance. Seals help prevent contaminants from entering the bearing and retain the lubricant. Different seal materials and designs have varying temperature limits. Common seal materials include rubber, metal, or felt. High-temperature seals or shields may be used to enhance the temperature tolerance of UCP bearings in demanding applications.

Generally, UCP bearings can handle a wide range of temperatures. Standard UCP bearings typically have a temperature range of -20°C to +120°C (-4°F to +248°F). However, it’s important to note that these temperature limits are approximate and can vary depending on the specific bearing design, materials, lubrication, and operating conditions.

For applications with higher temperature requirements, specialized high-temperature UCP bearings are available. These bearings are designed to withstand elevated temperatures and may have temperature limits ranging from 150°C to 350°C (302°F to 662°F) or even higher, depending on the specific design and materials used.

It’s crucial to consult the manufacturer’s documentation, specifications, or technical support to determine the exact temperature tolerance of a specific UCP bearing model. Proper selection and application of UCP bearings within their temperature limits help ensure reliable performance, prevent premature wear or failure, and contribute to the longevity of the bearing and the machinery it supports.

What are the signs of a failing UCP bearing?

A failing UCP bearing, also known as a pillow block bearing, can exhibit various signs and symptoms that indicate a potential problem. It’s important to recognize these signs early on to avoid further damage to the bearing and the machinery it supports. Here’s a detailed explanation of the common signs of a failing UCP bearing:

- Abnormal Noise: Unusual noises, such as grinding, scraping, clicking, or rumbling sounds, coming from the UCP bearing or the machinery it is installed in can indicate bearing failure. These noises may occur during operation or when the machinery is under load. Pay attention to any new or persistent noises that are not typical for the normal operation of the machinery.

- Excessive Vibration: A failing UCP bearing can cause increased vibration in the machinery. This vibration may be felt through the equipment or detected visually by observing excessive movement or shaking. Excessive vibration can lead to reduced performance, increased wear on other components, and potential safety hazards.

- Increased Temperature: If the UCP bearing is running at a higher temperature than usual, it can be a sign of bearing failure. Excessive heat can indicate increased friction, inadequate lubrication, or other issues with the bearing. Use caution when assessing the temperature and avoid touching hot surfaces directly.

- Reduced Performance: A failing UCP bearing can result in reduced performance of the machinery it supports. This can manifest as decreased efficiency, diminished output, or difficulty in achieving desired speeds or loads. The bearing’s inability to support the required operational demands can lead to performance issues in the machinery.

- Uneven or Excessive Wear: Inspect the UCP bearing for signs of wear or damage. Look for uneven wear patterns, pitting, scoring, or discoloration on the bearing surfaces. Excessive wear can indicate inadequate lubrication, contamination, misalignment, or other problems that can lead to bearing failure.

- Leakage or Contamination: If there is evidence of grease or lubricant leakage around the UCP bearing housing or seals, it may indicate a failing bearing. Additionally, the presence of contaminants, such as dirt, dust, or water, in or around the bearing can be a sign of compromised sealing or damage to the bearing’s protective barriers.

- Looseness or Excessive Play: A failing UCP bearing may exhibit looseness or excessive play when manually checking for movement. Excessive axial or radial play can indicate wear, misalignment, or internal damage within the bearing. This can result in decreased stability and compromised performance of the machinery.

If you observe any of these signs in your UCP bearing or the machinery it is installed in, it’s important to address the issue promptly. Continuing to operate with a failing UCP bearing can lead to further damage, increased downtime, and potential safety risks. It’s recommended to consult with a qualified technician, maintenance professional, or the bearing manufacturer’s technical support team for proper assessment, diagnosis, and replacement of the failing UCP bearing.

Remember that the signs of a failing UCP bearing may vary depending on the specific application, operating conditions, and other factors. Regular inspection, maintenance, and monitoring of the UCP bearings can help identify potential issues early on and prevent costly failures.

What are the dimensions of standard UCP bearings?

Standard UCP bearings, also known as pillow block bearings, come in various sizes and configurations to accommodate different shaft diameters. The dimensions of UCP bearings are typically specified by the bore diameter, overall length, width, and mounting hole spacing. Here’s a detailed explanation of the dimensions commonly associated with standard UCP bearings:

- Bore Diameter: The bore diameter refers to the inner diameter of the bearing, which determines the size of the shaft that can be accommodated. Standard UCP bearings are available in a range of bore diameters, such as 20 mm, 25 mm, 30 mm, 35 mm, 40 mm, 45 mm, 50 mm, and larger. The specific bore diameter required for your application will depend on the size of the shaft you are working with.

- Overall Length: The overall length of a UCP bearing refers to the distance between the outermost points of the bearing’s housing. It includes the length of the bearing itself and any additional extensions or flanges that may be present. The overall length can vary depending on the specific design and manufacturer, but it is typically standardized within certain size ranges.

- Width: The width of a UCP bearing refers to the measurement from one side of the bearing to the opposite side. It represents the thickness of the bearing’s housing. Similar to the overall length, the width can vary depending on the specific design and manufacturer, but it is often standardized within certain size ranges.

- Mounting Hole Spacing: UCP bearings have mounting holes on their base or flange, which are used to secure the bearing to a mounting surface. The mounting hole spacing refers to the distance between the centers of the mounting holes. This dimension is crucial for proper installation and compatibility with the corresponding mounting arrangement.

It’s important to note that the dimensions of UCP bearings can vary between manufacturers and series. Therefore, it is essential to consult the specific manufacturer’s documentation or product specifications to obtain accurate and detailed information about the dimensions of a particular UCP bearing model.

In summary, the dimensions of standard UCP bearings include the bore diameter, overall length, width, and mounting hole spacing. These dimensions can vary depending on the specific design and manufacturer. Refer to the manufacturer’s documentation for precise information on the dimensions of a particular UCP bearing model.

editor by CX 2024-05-17

wholesaler

Are there different grades of UCP bearings?

Yes, there are different grades or quality levels of UCP bearings, also known as pillow block bearings. These different grades are typically determined by the manufacturing standards and the specific requirements of the application. Here’s a detailed explanation of the different grades of UCP bearings:

1. Standard Grade: Standard grade UCP bearings are manufactured to meet industry-standard specifications and performance requirements. These bearings are commonly used in general industrial applications where moderate load capacities, speeds, and operating conditions are expected. Standard grade UCP bearings provide reliable performance within their specified limits and are widely available at competitive prices.

2. High-Precision Grade: High-precision grade UCP bearings are manufactured to tighter tolerances and stricter quality control standards. These bearings are designed for applications that require precise positioning, high speeds, low noise levels, and reduced vibration. High-precision UCP bearings are commonly used in industries such as robotics, machine tools, medical equipment, and optical devices. They offer superior performance and improved accuracy but are typically more expensive than standard grade bearings.

3. Specialty Grade: Specialty grade UCP bearings are designed to meet specific application requirements or industry standards. These bearings may have unique features, materials, or coatings to enhance their performance in specific environments or operating conditions. Examples of specialty UCP bearings include high-temperature bearings, corrosion-resistant bearings, food-grade bearings, and bearings for extreme load or high-speed applications. Specialty grade UCP bearings are typically selected for challenging or specialized applications and may have higher costs compared to standard grade bearings.

It’s important to note that the availability of different grades of UCP bearings may vary depending on the manufacturer and supplier. Some manufacturers may offer a range of grades to accommodate various customer needs, while others may focus on specific grades or specialize in certain industries.

When selecting UCP bearings, it’s crucial to consider the specific requirements of the application, including load capacity, operating conditions, precision requirements, and budget. Consulting with bearing manufacturers, distributors, or industry experts can help in determining the appropriate grade of UCP bearings for a particular application.

Additionally, it’s recommended to follow the manufacturer’s guidelines and specifications for the installation, lubrication, and maintenance of the selected grade of UCP bearings to ensure optimal performance and longevity.

How to replace a UCP bearing?

Replacing a UCP bearing, also known as a pillow block bearing, requires careful handling and following specific steps to ensure a successful replacement. Here’s a detailed explanation of the process to replace a UCP bearing:

- Gather the necessary tools: Before starting the replacement, gather the tools you will need, including a wrench or socket set, a puller or press (if needed), cleaning materials, and the replacement UCP bearing.

- Prepare the work area: Ensure that the work area is clean and well-lit. If the machinery is still operational, shut it down and follow proper lockout/tagout procedures to prevent accidental startup during the replacement process.

- Remove any obstructions: If there are any covers, guards, or other components obstructing access to the UCP bearing, remove them carefully to expose the bearing housing.

- Loosen the locking mechanism: Use a wrench or socket set to loosen the locking mechanism that secures the UCP bearing in place. This could be a set screw, collar, or other locking device. Follow the manufacturer’s instructions to identify and release the locking mechanism.

- Remove the UCP bearing: Once the locking mechanism is loosened, the UCP bearing can be removed from the housing. Apply gentle force if necessary, but avoid excessive impacts or prying that may damage the bearing or the housing.

- Clean the housing: Thoroughly clean the housing to remove any dirt, debris, or old lubricant. Use appropriate cleaning materials and ensure that the housing is dry before installing the new UCP bearing.

- Inspect and prepare the replacement bearing: Before installing the new UCP bearing, inspect it for any signs of damage or defects. Ensure that the bore and outer surfaces are clean and free from any contaminants. If necessary, apply a suitable lubricant to the bearing per the manufacturer’s recommendations.

- Install the new UCP bearing: Carefully position the new UCP bearing into the housing, aligning the bore with the shaft. Apply even pressure to press the bearing into place, ensuring it is seated securely. Follow the manufacturer’s instructions for any specific installation requirements, such as tightening torque for the locking mechanism.

- Secure the locking mechanism: Once the new UCP bearing is installed, tighten the locking mechanism to secure it in place. Again, follow the manufacturer’s instructions for the specific tightening procedure and torque value.

- Reinstall any obstructions: Put back any covers, guards, or components that were removed earlier to restore the machinery to its original configuration.

- Test and verify: After the replacement is complete, test the machinery to ensure proper operation of the new UCP bearing. Monitor for any unusual noise, vibration, or other issues that may indicate incorrect installation or other problems.

It’s important to note that the specific steps for replacing a UCP bearing may vary depending on the machinery and the manufacturer’s recommendations. Always refer to the manufacturer’s documentation, maintenance manuals, or technical support for the most accurate and detailed instructions for your specific UCP bearing and machinery.

Additionally, if you are unsure or uncomfortable with performing the replacement yourself, it’s recommended to seek the assistance of a qualified technician or maintenance professional to ensure the proper installation and functioning of the UCP bearing.

What is a UCP bearing?

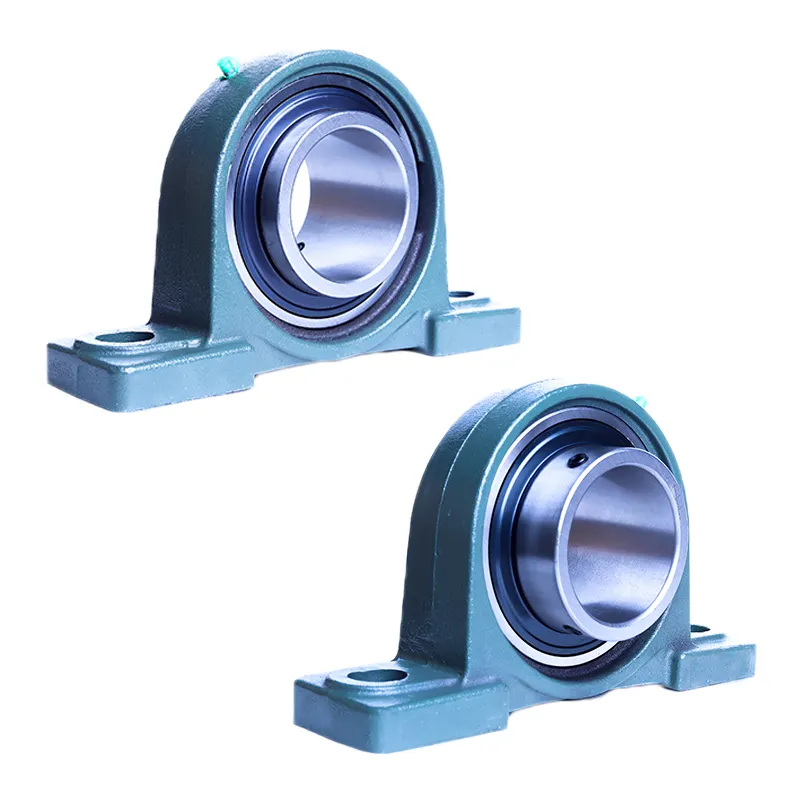

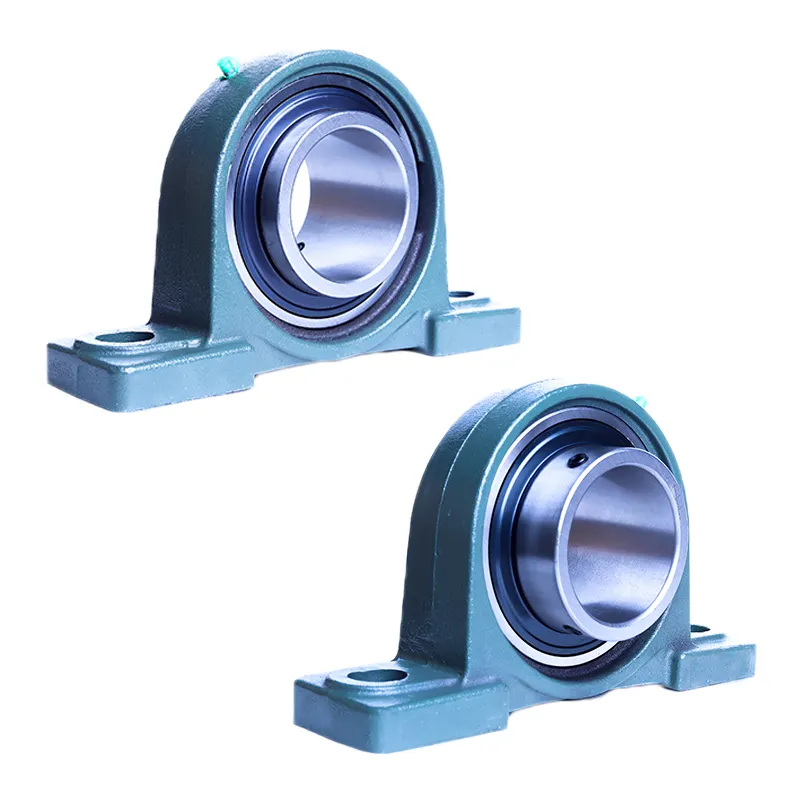

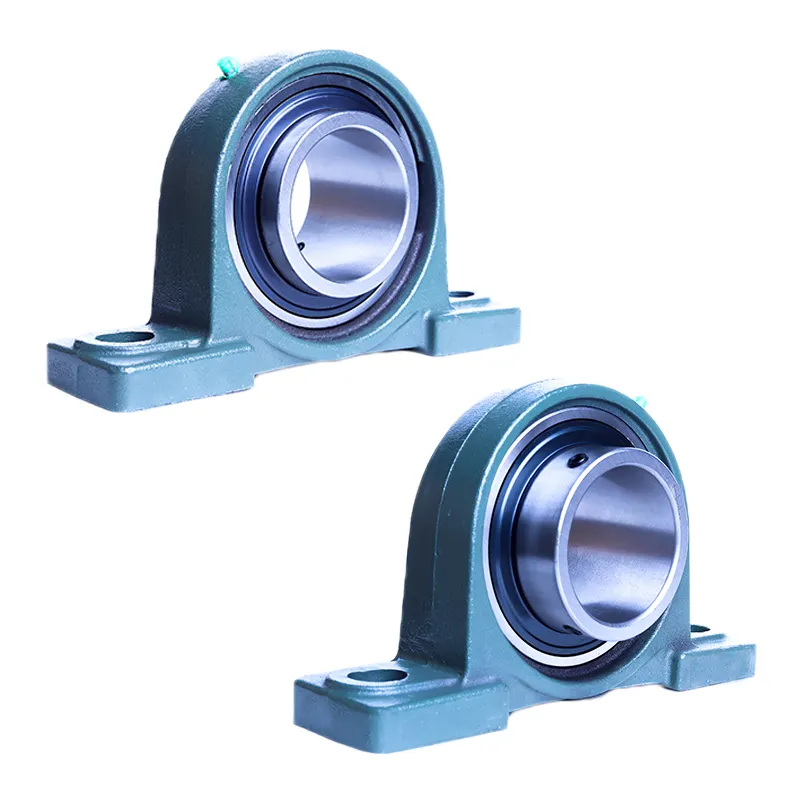

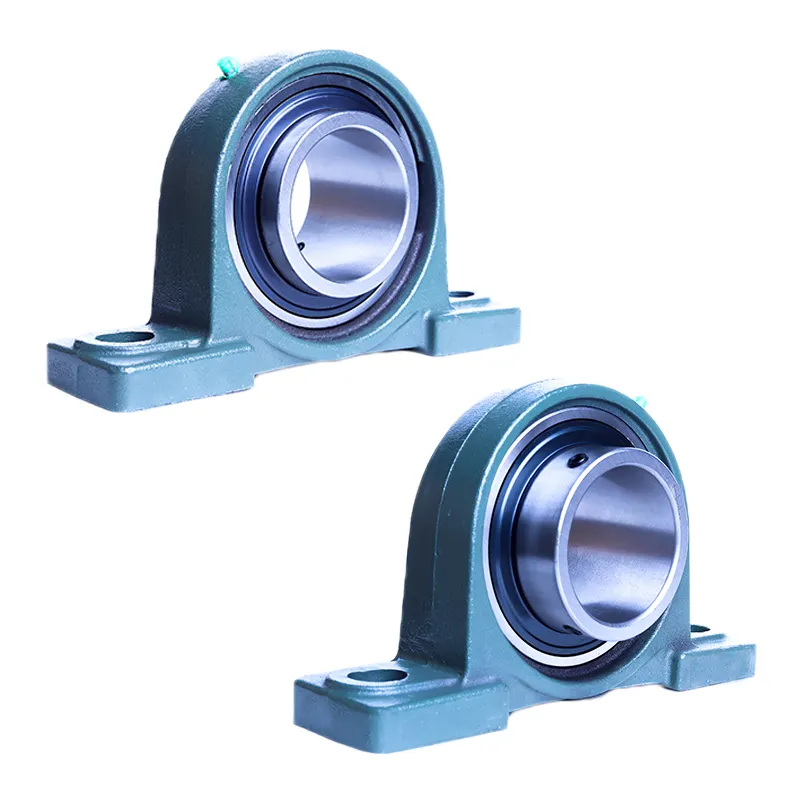

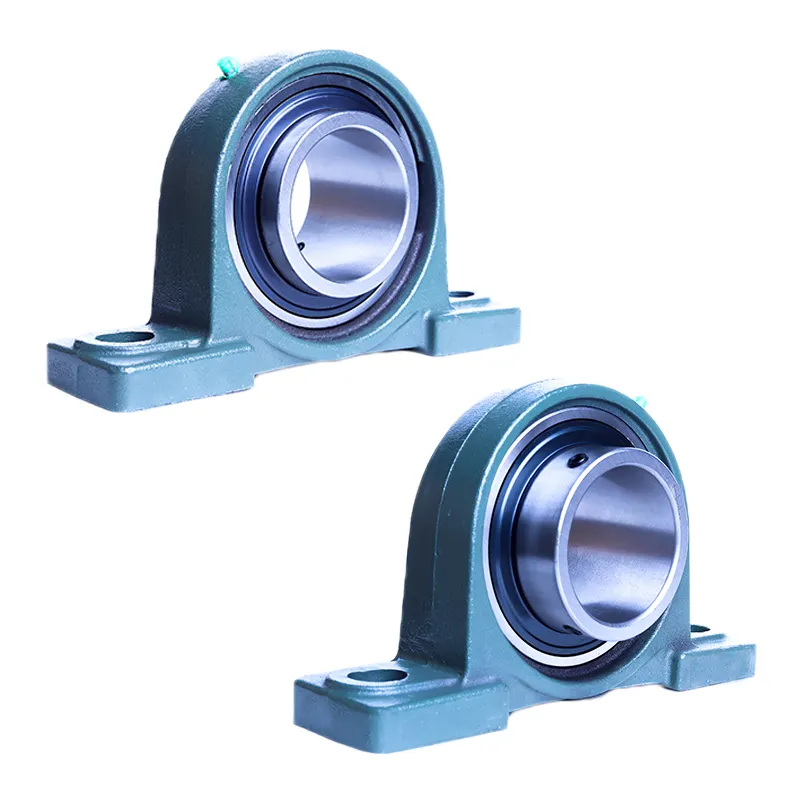

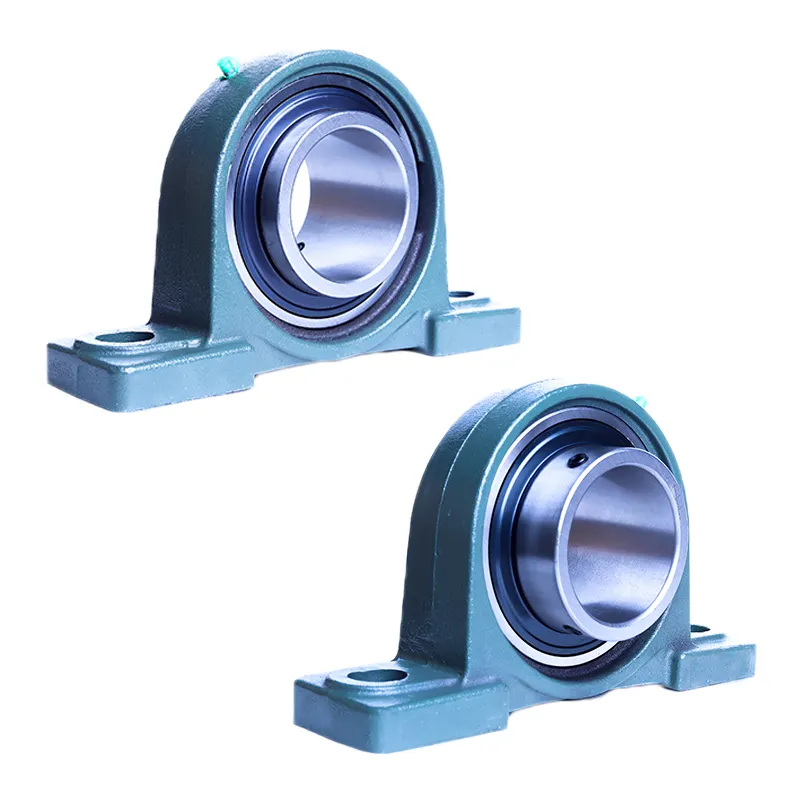

A UCP bearing, also known as a pillow block bearing, is a type of mounted bearing commonly used in various industrial applications. It is designed to provide support and facilitate rotational or linear motion in machinery and equipment. Here’s a detailed explanation:

A UCP bearing consists of a bearing unit and a housing. The bearing unit typically includes a rolling element bearing, such as a ball bearing or a roller bearing, which enables smooth and low-friction motion. The housing, often made of cast iron or pressed steel, serves as a support structure for the bearing unit and provides protection against contaminants and external elements.

The term “UCP” stands for “Unit with Cast Iron Pillow Block,” referring to the common use of cast iron housings in UCP bearings. The housing is typically shaped like a pillow or block, with a flat base and mounting holes for easy installation and attachment to a machine or structure.

UCP bearings are widely used in various applications, including conveyor systems, agricultural machinery, industrial equipment, HVAC systems, and more. They offer several advantages:

- Easy Installation: UCP bearings are designed for easy installation and mounting. The housing’s flat base and pre-drilled mounting holes allow for straightforward attachment to a support structure or machine.

- Simple Maintenance: UCP bearings are relatively easy to maintain. They often feature removable bearing units, allowing for inspection, lubrication, and replacement when necessary. This simplifies maintenance tasks and reduces downtime.

- Load Support: UCP bearings are capable of supporting different loads, including radial and axial loads. The specific load capacity depends on the type and size of the bearing unit used within the UCP assembly.

- Protection and Contamination Resistance: The housing of a UCP bearing provides protection to the bearing unit against contaminants, moisture, and other external elements. This helps extend the bearing’s service life and maintain its performance.

- Alignment Compensation: UCP bearings often have self-aligning capabilities, allowing them to compensate for minor misalignments between the shaft and the housing. This feature helps reduce stress and wear on the bearing, enhancing its reliability and longevity.

UCP bearings are available in various sizes, configurations, and bearing types to accommodate different application requirements. It is important to select the appropriate UCP bearing based on factors such as load capacity, operating conditions, and environmental considerations.

In summary, a UCP bearing, or pillow block bearing, is a mounted bearing unit that provides support and facilitates motion in industrial applications. With their easy installation, maintenance convenience, load support, protection, and alignment compensation features, UCP bearings are widely used to ensure reliable and efficient operation of machinery and equipment.

editor by CX 2024-05-17

China wholesaler China Supply High Speed UCP203 UC210 UC211 UC212 Pillow Block Bearing for Machinery, Agriculture Machinery manufacturer

Product Description

Company Profile

Yiboyuan (HangZhou City) Precision Machinery Co., Ltd. is located in Bacha Road Industrial Park, HangZhou City, HangZhou City, ZheJiang Province, is a professional manufacturer of linear bearings

integrating design, research and development, production and sales. The company’s main products are: YBYZ linear bearings, YBYZ linear flange bearings, YBYZ nickel-plated linear bearings, YBYZ steel linear bearings, YBYZ box sliders, YBYZ smooth shaft supports, YBYZ self lubricating bearings, YBYZ outer steel inner copper linear bearings, YBYZ aluminum-plastic linear bearings, YBYZ all-plastic linear

bearings, YBYZ graphite copper sleeved linear bearings, YBYZ fixed rings, nut seats, cross shaft brackets and so on. Yiboyuan linear bearings should build the most complete linear bearing enterprises and smooth shaft supporting products at home and abroad, and solve one-stop procurement services for automation companies.Our mission – to create revenue benefits for customers, provide high-quality products for the market, and create a stage for employees to play, the future Yiboyuan is a high-tech, service-oriented, international Yiboyuan, to build a century-old brand is our continuous goal.

Brand trademark registration

Yiboyuan (HangZhou) Precision Machinery Co., Ltd. is a professional manufacturer of linear motion products with many years of experience. And has its own registered brand YBYZ, we specialize in the production of linear bearings, plain bearings, shaft bearings, box sliders, self-lubricating copper sleeve. Good quality, competitive price. Our company is located in HangZhou City, ZheJiang Province. Close to HangZhou Port, ZheJiang Port.

Our products are widely used in precision machinery, fitness equipment, printing presses, packaging machines, medical and food machinery, textile machinery and other machinery and auxiliary equipment. Our products sell well in North America, Western Europe, Australia, Southeast Asia, the Middle East, South America and other regions.

Product Description:

| PRODUCTS AND WEIGHT LIST OF PILLOW BLOCK | |||||||||||||

| ITEM | KGS | ITEM | KGS | ITEM | KGS | ITEM | KGS | ITEM | KGS | ITEM | KGS | ITEM | KGS |

| UC201 | 0.2 | UCP201 | 0.61 | UCF201 | 0.59 | UCFL201 | 0.44 | UCT201 | 0.75 | UCFC201 | 0.71 | UCPA201 | 0.56 |

| UC201-8 | 0.19 | UCP201-8 | 0.6 | UCF201-8 | 0.58 | UCFL201-8 | 0.43 | UCT201-8 | 0.74 | UCFC201-8 | 0.7 | UCPA201-8 | 0.55 |

| UC202 | 0.18 | UCP202 | 0.59 | UCF202 | 0.57 | UCFL202 | 0.42 | UCT202 | 0.73 | UCFC202 | 0.69 | UCPA202 | 0.54 |

| UC202-10 | 0.18 | UCP202-10 | 0.59 | UCF202-10 | 0.57 | UCFL202-10 | 0.42 | UCT202-10 | 0.73 | UCFC202-10 | 0.69 | UCPA202-10 | 0.54 |

| UC203 | 0.17 | UCP203 | 0.58 | UCF203 | 0.56 | UCFL203 | 0.41 | UCT203 | 0.72 | UCFC203 | 0.68 | UCPA203 | 0.53 |

| UC204 | 0.15 | UCP204 | 0.61 | UCF204 | 0.54 | UCFL204 | 0.39 | UCT204 | 0.7 | UCFC204 | 0.66 | UCPA204 | 0.51 |

| UC204-12 | 0.16 | UCP204-12 | 0.62 | UCF204-12 | 0.55 | UCFL204-12 | 0.4 | UCT204-12 | 0.71 | UCFC204-12 | 0.67 | UCPA204-12 | 0.52 |

| UC205 | 0.19 | UCP205 | 0.69 | UCF205 | 0.66 | UCFL205 | 0.57 | UCT205 | 0.73 | UCFC205 | 0.92 | UCPA205 | 0.68 |

| UC205-14 | 0.22 | UCP205-14 | 0.72 | UCF205-14 | 0.69 | UCFL205-14 | 0.6 | UCT205-14 | 0.76 | UCFC205-14 | 0.95 | UCPA205-14 | 0.71 |

| UC205-15 | 0.2 | UCP205-15 | 0.7 | UCF205-15 | 0.67 | UCFL205-15 | 0.58 | UCT205-15 | 0.74 | UCFC205-15 | 0.93 | UCPA205-15 | 0.69 |

| UC205-16 | 0.19 | UCP205-16 | 0.69 | UCF205-16 | 0.66 | UCFL205-16 | 0.57 | UCT205-16 | 0.73 | UCFC205-16 | 0.92 | UCPA205-16 | 0.68 |

| UC206 | 0.3 | UCP206 | 1.13 | UCF206 | 0.93 | UCFL206 | 0.76 | UCT206 | 1.17 | UCFC206 | 1.21 | UCPA206 | 0.99 |

| UC206-18 | 0.32 | UCP206-18 | 1.15 | UCF206-18 | 0.95 | UCFL206-18 | 0.78 | UCT206-18 | 1.19 | UCFC206-18 | 1.23 | UCPA206-18 | 1.01 |

| UC206-19 | 0.3 | UCP206-19 | 1.13 | UCF206-19 | 0.93 | UCFL206-19 | 0.76 | UCT206-19 | 1.17 | UCFC206-19 | 1.21 | UCPA206-19 | 0.99 |

| UC206-20 | 0.28 | UCP206-20 | 1.11 | UCF206-20 | 0.91 | UCFL206-20 | 0.74 | UCT206-20 | 1.15 | UCFC206-20 | 1.19 | UCPA206-20 | 0.97 |

| UC207 | 0.45 | UCP207 | 1.34 | UCF207 | 1.2 | UCFL207 | 1.05 | UCT207 | 1.45 | UCFC207 | 1.5 | UCPA207 | 1.42 |

| UC207-20 | 0.5 | UCP207-20 | 1.39 | UCF207-20 | 1.25 | UCFL207-20 | 1.1 | UCT207-20 | 1.5 | UCFC207-20 | 1.55 | UCPA207-20 | 1.47 |

| UC207-21 | 0.48 | UCP207-21 | 1.37 | UCF207-21 | 1.23 | UCFL207-21 | 1.08 | UCT207-21 | 1.48 | UCFC207-21 | 1.53 | UCPA207-21 | 1.45 |

| UC207-22 | 0.45 | UCP207-22 | 1.34 | UCF207-22 | 1.2 | UCFL207-22 | 1.05 | UCT207-22 | 1.45 | UCFC207-22 | 1.5 | UCPA207-22 | 1.42 |

| UC207-23 | 0.43 | UCP207-23 | 1.32 | UCF207-23 | 1.18 | UCFL207-23 | 1.03 | UCT207-23 | 1.43 | UCFC207-23 | 1.48 | UCPA207-23 | 1.4 |

| UC208 | 0.59 | UCP208 | 1.8 | UCF208 | 1.57 | UCFL208 | 1.34 | UCT208 | 2.11 | UCFC208 | 1.87 | UCPA208 | 1.64 |

| UC208-24 | 0.64 | UCP208-24 | 1.85 | UCF208-24 | 1.62 | UCFL208-24 | 1.39 | UCT208-24 | 2.16 | UCFC208-24 | 1.92 | UCPA208-24 | 1.69 |

| UC209 | 0.65 | UCP209 | 1.84 | UCF209 | 1.76 | UCFL209 | 1.7 | UCT209 | 2.18 | UCFC209 | 2.34 | UCPA209 | 1.8 |

| UC209-26 | 0.74 | UCP209-26 | 1.93 | UCF209-26 | 1.85 | UCFL209-26 | 1.79 | UCT209-26 | 2.27 | UCFC209-26 | 2.43 | UCPA209-26 | 1.89 |

| UC209-27 | 0.71 | UCP209-27 | 1.9 | UCF209-27 | 1.82 | UCFL209-27 | 1.76 | UCT209-27 | 2.24 | UCFC209-27 | 2.4 | UCPA209-27 | 1.86 |

| UC209-28 | 0.68 | UCP209-28 | 1.87 | UCF209-28 | 1.79 | UCFL209-28 | 1.73 | UCT209-28 | 2.21 | UCFC209-28 | 2.37 | UCPA209-28 | 1.83 |

| UC210 | 0.74 | UCP210 | 2.49 | UCF210 | 2.05 | UCFL210 | 1.92 | UCT210 | 2.35 | UCFC210 | 2.72 | UCPA210 | 2.23 |

| ITEM | KGS | ITEM | KGS | ITEM | KGS | ITEM | KGS | ITEM | KGS | ITEM | KGS | ITEM | KGS |

| UC210-30 | 0.85 | UCP210-30 | 2.6 | UCF210-30 | 2.16 | UCFL210-30 | 2.03 | UCT210-30 | 2.46 | UCFC210-30 | 2.83 | UCPA210-30 | 2.34 |

| UC210-31 | 0.76 | UCP210-31 | 2.51 | UCF210-31 | 2.07 | UCFL210-31 | 1.94 | UCT210-31 | 2.37 | UCFC210-31 | 2.74 | UCPA210-31 | 2.25 |

| UC210-32 | 0.71 | UCP210-32 | 2.46 | UCF210-32 | 2.02 | UCFL210-32 | 1.89 | UCT210-32 | 2.32 | UCFC210-32 | 2.69 | UCPA210-32 | 2.2 |

| UC211 | 0.96 | UCP211 | 2.91 | UCF211 | 2.96 | UCFL211 | 2.73 | UCT211 | 3.56 | UCFC211 | 3.66 | UCPA211 | 2.79 |

| UC211-32 | 1.1 | UCP211-32 | 3.05 | UCF211-32 | 3.1 | UCFL211-32 | 2.87 | UCT211-32 | 3.7 | UCFC211-32 | 3.8 | UCPA211-32 | 2.93 |

| UC211-34 | 1.01 | UCP211-34 | 2.96 | UCF211-34 | 3.01 | UCFL211-34 | 2.78 | UCT211-34 | 3.61 | UCFC211-34 | 3.71 | UCPA211-34 | 2.84 |

| UC211-35 | 0.93 | UCP211-35 | 2.88 | UCF211-35 | 2.93 | UCFL211-35 | 2.7 | UCT211-35 | 3.53 | UCFC211-35 | 3.63 | UCPA211-35 | 2.76 |

| UC212 | 1.38 | UCP212 | 3.98 | UCF212 | 3.54 | UCFL212 | 3.56 | UCT212 | 4.23 | UCFC212 | 4.58 | UCPA212 | 3.66 |

| UC212-36 | 1.51 | UCP212-36 | 4.11 | UCF212-36 | 3.67 | UCFL212-36 | 3.69 | UCT212-36 | 4.36 | UCFC212-36 | 4.71 | UCPA212-36 | 3.79 |

| UC212-38 | 1.37 | UCP212-38 | 3.97 | UCF212-38 | 3.53 | UCFL212-38 | 3.55 | UCT212-38 | 4.22 | UCFC212-38 | 4.57 | UCPA212-38 | 3.65 |

| UC212-39 | 1.27 | UCP212-39 | 3.87 | UCF212-39 | 3.43 | UCFL212-39 | 3.45 | UCT212-39 | 4.12 | UCFC212-39 | 4.47 | UCPA212-39 | 3.55 |

| UC213 | 1.67 | UCP213 | 5.17 | UCF213 | 4.92 | UCFL213 | 4.37 | UCT213 | 6.04 | UCFC213 | 5.07 | ||

| UC213-40 | 1.75 | UCP213-40 | 5.25 | UCF213-40 | 5 | UCFL213-40 | 4.45 | UCT213-40 | 6.12 | UCFC213-40 | 5.15 | ||

| UC214 | 1.95 | UCP214 | 5.57 | UCF214 | 5.09 | UCFL214 | 4.95 | UCT214 | 6.35 | UCFC214 | 6.15 | ||

| UC214-44 | 1.95 | UCP214-44 | 5.57 | UCF214-44 | 5.09 | UCFL214-44 | 4.95 | UCT214-44 | 6.35 | UCFC214-44 | 6.15 | ||

| UC215 | 2.14 | UCP215 | 6.14 | UCF215 | 5.79 | UCFL215 | 5.18 | UCT215 | 6.6 | UCFC215 | 6.79 | ||

| UC215-47 | 2.17 | UCP215-47 | 6.17 | UCF215-47 | 5.82 | UCFL215-47 | 5.21 | UCT215-47 | 6.63 | UCFC215-47 | 6.82 | ||

| UC215-48 | 2.06 | UCP215-48 | 6.06 | UCF215-48 | 5.71 | UCFL215-48 | 5.1 | UCT215-48 | 6.52 | UCFC215-48 | 6.71 | ||

| UC216 | 2.61 | UCP216 | 7.11 | UCF216 | 6.91 | UCFL216 | 6.36 | UCT216 | 7.24 | UCFC216 | 8.01 | ||

| UC217 | 3.38 | UCP217 | 9.18 | UCF217 | 8.63 | UCFL217 | 7.68 | UCT217 | 10.33 | UCFC217 | 9.18 | ||

| UC218 | 4 | UCP218 | 10.63 | UCF218 | 9.5 | UCFL218 | 9.54 | UCT218 | 11.8 | UCFC218 | 11.3 | ||

| UC218-56 | 4.1 | UCP218-56 | 10.73 | UCF218-56 | 9.6 | UCFL218-56 | 9.64 | UCT218-56 | 11.9 | UCFC218-56 | 11.4 | ||

| UCP220 | 14.5 | UCF220 | 13 | ||||||||||

| ITEM | KGS | ITEM | KGS | ITEM | KGS | ITEM | KGS | ITEM | KGS | ITEM | KGS | ITEM | KGS |

| UC305 | 0.34 | UCP305 | 1.28 | SA201 | 0.13 | SB201 | 0.1 | UK205 | 0.16 | NA204 | 0.2 | UKP205 | 0.66 |

| UC306 | 0.52 | UCP306 | 1.72 | SA202 | 0.12 | SB202 | 0.09 | UK206 | 0.25 | NA205 | 0.25 | UKP206 | 1.08 |

| UC307 | 0.68 | UCP307 | 2.33 | SA203 | 0.1 | SB203 | 0.08 | UK207 | 0.36 | NA206 | 0.38 | UKP207 | 1.25 |

| UC308 | 0.95 | UCP308 | 3.01 | SA204 | 0.16 | SB204 | 0.12 | UK208 | 0.44 | NA207 | 0.54 | UKP208 | 1.65 |

| UC309 | 1.22 | UCP309 | 3.77 | SA205 | 0.19 | SB205 | 0.16 | UK209 | 0.51 | NA208 | 0.73 | UKP209 | 1.7 |

| UC310 | 1.57 | UCP310 | 5.47 | SA206 | 0.3 | SB206 | 0.25 | UK210 | 0.56 | NA209 | 0.79 | UKP210 | 2.31 |

| UC311 | 1.98 | UCP311 | 6.83 | SA207 | 0.45 | SB207 | 0.36 | UK211 | 0.74 | NA210 | 0.95 | UKP211 | 2.69 |

| UC312 | 2.45 | UCP312 | 8.15 | SA208 | 0.6 | SB208 | 0.45 | UK212 | 1 | UKP212 | 3.6 | ||

| UC313 | 3.14 | UCP313 | 9.41 | SA209 | 0.64 | SB209 | 0.56 | UK213 | 1.27 | UKP213 | 4.77 | ||

| UC314 | 3.62 | UCP314 | 11.08 | SA210 | 0.71 | SB210 | 0.62 | UK215 | 1.52 | UKP215 | 5.52 | ||

| UC315 | 4.5 | UCP315 | 13.8 | UK216 | 1.84 | UKP216 | 6.34 | ||||||

| UC316 | 5.2 | UCP316 | 16.2 | UK217 | 2.34 | UKP217 | 8.14 | ||||||

| UC317 | 6.63 | UK218 | 2.85 | UKP218 | 9.48 | ||||||||

| UC318 | 7.33 | ||||||||||||

| UC319 | 8.37 | ||||||||||||

| UC320 | 10.32 | ||||||||||||

Our packing:

* Industrial pakage

Address: Industrial Park, Bachalu Town, HangZhou City.HangZhou City, ZheJiang Province.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Aligning Bearing |

|---|---|

| Separated: | Unseparated |

| Feature: | Vacuum, Magnetically, Low Temperature, Corrosion Resistant, High Temperature, High Speed |

| Rows Number: | Multiple |

| Raceway: | Crowned Raceway |

| Material: | Bearing Steel |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are UCP bearings available in stainless steel?

Yes, UCP bearings are available in stainless steel variants. Stainless steel UCP bearings are specifically designed and manufactured using stainless steel materials for applications that require corrosion resistance, hygiene, or specific environmental conditions. Here’s a detailed explanation:

1. Corrosion Resistance: Stainless steel UCP bearings are highly resistant to corrosion, making them suitable for applications where exposure to moisture, chemicals, or other corrosive substances is a concern. The stainless steel material, typically AISI 304 or AISI 316, provides excellent resistance to rust and oxidation, ensuring extended service life in harsh environments.

2. Hygienic Applications: Stainless steel UCP bearings are commonly used in industries such as food and beverage, pharmaceuticals, and medical equipment, where cleanliness and hygiene are critical. These bearings are resistant to bacterial growth, easy to clean, and comply with strict industry regulations and standards for hygiene and sanitation.

3. High-Temperature Environments: Stainless steel UCP bearings can also withstand higher temperatures compared to standard UCP bearings made of other materials. This makes them suitable for applications where elevated temperatures are present, such as ovens, kilns, or high-temperature processing equipment.

4. Special Environmental Conditions: Stainless steel UCP bearings are chosen for applications in specific environmental conditions where other materials may not be suitable. For example, in outdoor or marine environments, where exposure to saltwater or corrosive gases is prevalent, stainless steel bearings offer superior resistance and durability.

Stainless steel UCP bearings typically have the same design and dimensions as standard UCP bearings, but with stainless steel materials used for the bearing components, including the inner and outer rings, balls, and cage. The sealing elements, such as seals or shields, may also be made of stainless steel or other compatible materials.

It’s important to note that stainless steel UCP bearings may have limitations in terms of load capacity and operating speed compared to their counterparts made of other materials, such as chrome steel. The specific performance characteristics and limitations of stainless steel UCP bearings may vary depending on the manufacturer and the grade of stainless steel used.

When selecting stainless steel UCP bearings, it’s essential to consider the application requirements, including load capacity, temperature range, environmental conditions, and regulatory compliance. Consulting with bearing manufacturers, distributors, or industry experts can help in determining the appropriate stainless steel UCP bearings for a particular application.

Proper installation, lubrication, and maintenance practices should also be followed to ensure optimal performance and longevity of stainless steel UCP bearings in their intended applications.

How to choose the right UCP bearing for my machinery?

Choosing the right UCP bearing, also known as a pillow block bearing, for your machinery is crucial to ensure optimal performance, reliability, and longevity. Here’s a detailed explanation of the factors to consider when selecting a UCP bearing:

- Load Requirements: Evaluate the load requirements of your machinery, including the magnitude and direction of the loads. Consider factors such as radial loads, axial loads, and moment loads. Ensure that the UCP bearing you choose has a load capacity that is suitable for the anticipated loads in your application.

- Shaft Diameter: Determine the shaft diameter of your machinery and select a UCP bearing with a corresponding bore size. The bore size of the UCP bearing should match the shaft diameter to ensure proper fit and alignment. It’s important to measure the shaft accurately and consider any potential expansion or misalignment during operation.

- Operating Conditions: Assess the operating conditions of your machinery, including factors such as speed, temperature, and environmental conditions. Choose a UCP bearing that is designed to withstand the anticipated operating conditions. Consider factors like maximum speed rating, temperature range, lubrication requirements, and resistance to contaminants or moisture.

- Sealing and Protection: Depending on the application requirements, consider whether additional sealing or protection is necessary for the UCP bearing. Seals or shields can help prevent the ingress of dirt, dust, or contaminants, prolonging the bearing’s life and reducing maintenance needs. Choose a UCP bearing with appropriate sealing options, such as rubber seals or metal shields, based on the specific environmental conditions.

- Alignment Capability: Evaluate the alignment capabilities of the UCP bearing. Some UCP bearings have self-aligning features that can compensate for minor shaft misalignment. If your machinery is prone to misalignment or has flexible shafts, consider choosing a UCP bearing with self-aligning properties to minimize excessive loads and premature wear.

- Manufacturer and Quality: Select UCP bearings from reputable manufacturers known for their quality and reliability. Consider manufacturers with a strong track record in bearing production and a wide range of product offerings. Research customer reviews, consult with industry experts, and consider the manufacturer’s reputation for producing durable and high-performance UCP bearings.

By considering these factors and choosing a UCP bearing that aligns with your machinery’s specific requirements, you can ensure optimal performance and minimize the risk of premature failures or downtime. It’s recommended to consult with bearing specialists, engineers, or the manufacturer’s technical support team for additional guidance and assistance in selecting the most suitable UCP bearing for your machinery.

Remember that the specific requirements for UCP bearings may vary depending on the application, industry, and machinery specifications. Always refer to the manufacturer’s documentation, specifications, and guidelines for the most accurate and detailed information.

Who are the leading manufacturers of UCP bearings?

Several leading manufacturers specialize in producing high-quality UCP bearings, also known as pillow block bearings. These manufacturers have a strong reputation for their expertise in bearing manufacturing and offer a wide range of UCP bearing options. Here’s a detailed explanation of some of the leading manufacturers of UCP bearings:

- SKF: SKF is a renowned global manufacturer of bearings and related products. They offer a comprehensive range of UCP bearings that are known for their reliability, performance, and durability. SKF’s UCP bearings are designed to meet various industrial requirements and are available in different sizes and configurations.

- NSK: NSK is a well-established manufacturer of bearings, including UCP bearings. They have a strong presence in the market and are known for their high-quality and precision-engineered products. NSK’s UCP bearings are designed to provide excellent performance in diverse applications and are available in various sizes and materials.

- NTN: NTN is a trusted manufacturer of bearings and precision products. They offer a wide range of UCP bearings that are known for their quality, reliability, and long service life. NTN’s UCP bearings are designed to meet industry standards and are available in different sizes and configurations to suit various applications.

- Timken: Timken is a reputable manufacturer of bearings and power transmission products. They manufacture UCP bearings that are known for their robustness, precision, and exceptional performance. Timken’s UCP bearings are designed to withstand heavy loads and harsh operating conditions, making them suitable for a wide range of industrial applications.

- FAG: FAG, part of the Schaeffler Group, is a leading manufacturer of bearings and related products. They offer a diverse range of UCP bearings that are known for their high-quality construction and superior performance. FAG’s UCP bearings are designed to meet demanding industrial requirements and are available in various sizes and designs.

These are just a few examples of leading manufacturers of UCP bearings. Other reputable manufacturers in the industry include Koyo, Nachi, RHP, and FYH, among others. It’s worth noting that the availability and popularity of specific manufacturers may vary depending on your location and industry requirements.

When selecting a UCP bearing, it’s important to consider factors such as product quality, reliability, technical support, and availability. Consulting with local distributors, reviewing manufacturer catalogs, and considering customer reviews can help you make an informed decision about the most suitable manufacturer for your specific needs.

In summary, leading manufacturers of UCP bearings include SKF, NSK, NTN, Timken, and FAG, among others. These manufacturers are known for their high-quality products and extensive expertise in bearing manufacturing.

editor by CX 2024-05-16

Custom

How long do UCP bearings last?

The lifespan of UCP bearings, also known as pillow block bearings, can vary depending on several factors. Here’s a detailed explanation of the factors that can influence the longevity of UCP bearings:

- Operating Conditions: The operating conditions play a significant role in the lifespan of UCP bearings. Factors such as the load magnitude, speed, temperature, and environmental conditions can impact the bearing’s performance and durability. Bearings operating under heavy loads, high speeds, or in harsh environments may experience increased wear and fatigue, potentially reducing their lifespan.

- Maintenance and Lubrication: Proper maintenance practices, including regular inspection, cleaning, and lubrication, can significantly extend the lifespan of UCP bearings. Adequate lubrication forms a protective film between the rolling elements and the bearing races, reducing friction and wear. Insufficient or improper lubrication can lead to increased friction, heat generation, and premature failure of the bearings.

- Quality and Material: The quality and material composition of UCP bearings can influence their lifespan. Bearings made from high-quality materials, such as stainless steel or chrome steel, are generally more resistant to wear, corrosion, and fatigue. Careful selection of UCP bearings from reputable manufacturers, considering factors like load ratings and performance specifications, can contribute to longer bearing life.

- Installation and Alignment: Proper installation and alignment of UCP bearings are critical for their longevity. Ensuring correct shaft and housing fits, accurate alignment of the bearing components, and appropriate tightening of locking mechanisms help distribute loads evenly and prevent excessive stress or misalignment. Improper installation can lead to premature wear, increased friction, and reduced bearing life.

- Application-Specific Factors: The specific application in which UCP bearings are used can influence their lifespan. Factors like shock loads, vibration, contamination, and the presence of corrosive substances can affect bearing performance and durability. Adequate protection measures, such as seals or shields, can help mitigate these factors and prolong bearing life.

Given these factors, it can be challenging to provide an exact lifespan for UCP bearings. In some applications, UCP bearings can last for many years or even decades if properly maintained and operated within their specified limits. However, in demanding or unfavorable conditions, the lifespan of UCP bearings may be shorter, requiring more frequent inspection and replacement.

It’s important to monitor the condition of UCP bearings regularly and look for signs of wear, damage, or performance degradation. Any unusual noise, excessive vibration, increased temperature, or other signs of bearing failure should be addressed promptly to avoid further damage to the bearings and the machinery they support.

Consulting the manufacturer’s documentation, maintenance guidelines, or seeking advice from bearing experts can provide more specific information regarding the expected lifespan of UCP bearings in a particular application or operating environment.

What are the signs of a failing UCP bearing?

A failing UCP bearing, also known as a pillow block bearing, can exhibit various signs and symptoms that indicate a potential problem. It’s important to recognize these signs early on to avoid further damage to the bearing and the machinery it supports. Here’s a detailed explanation of the common signs of a failing UCP bearing:

- Abnormal Noise: Unusual noises, such as grinding, scraping, clicking, or rumbling sounds, coming from the UCP bearing or the machinery it is installed in can indicate bearing failure. These noises may occur during operation or when the machinery is under load. Pay attention to any new or persistent noises that are not typical for the normal operation of the machinery.

- Excessive Vibration: A failing UCP bearing can cause increased vibration in the machinery. This vibration may be felt through the equipment or detected visually by observing excessive movement or shaking. Excessive vibration can lead to reduced performance, increased wear on other components, and potential safety hazards.

- Increased Temperature: If the UCP bearing is running at a higher temperature than usual, it can be a sign of bearing failure. Excessive heat can indicate increased friction, inadequate lubrication, or other issues with the bearing. Use caution when assessing the temperature and avoid touching hot surfaces directly.

- Reduced Performance: A failing UCP bearing can result in reduced performance of the machinery it supports. This can manifest as decreased efficiency, diminished output, or difficulty in achieving desired speeds or loads. The bearing’s inability to support the required operational demands can lead to performance issues in the machinery.

- Uneven or Excessive Wear: Inspect the UCP bearing for signs of wear or damage. Look for uneven wear patterns, pitting, scoring, or discoloration on the bearing surfaces. Excessive wear can indicate inadequate lubrication, contamination, misalignment, or other problems that can lead to bearing failure.

- Leakage or Contamination: If there is evidence of grease or lubricant leakage around the UCP bearing housing or seals, it may indicate a failing bearing. Additionally, the presence of contaminants, such as dirt, dust, or water, in or around the bearing can be a sign of compromised sealing or damage to the bearing’s protective barriers.

- Looseness or Excessive Play: A failing UCP bearing may exhibit looseness or excessive play when manually checking for movement. Excessive axial or radial play can indicate wear, misalignment, or internal damage within the bearing. This can result in decreased stability and compromised performance of the machinery.

If you observe any of these signs in your UCP bearing or the machinery it is installed in, it’s important to address the issue promptly. Continuing to operate with a failing UCP bearing can lead to further damage, increased downtime, and potential safety risks. It’s recommended to consult with a qualified technician, maintenance professional, or the bearing manufacturer’s technical support team for proper assessment, diagnosis, and replacement of the failing UCP bearing.

Remember that the signs of a failing UCP bearing may vary depending on the specific application, operating conditions, and other factors. Regular inspection, maintenance, and monitoring of the UCP bearings can help identify potential issues early on and prevent costly failures.

Where can I buy UCP bearings?

When looking to purchase UCP bearings, there are several options available to you. Here’s a detailed explanation of where you can buy UCP bearings:

1. Local Bearing Suppliers: One of the most convenient options is to visit local bearing suppliers or distributors in your area. These suppliers specialize in providing a wide range of bearings, including UCP bearings. They typically have knowledgeable staff who can assist you in selecting the right UCP bearing for your specific application. You can search online directories or check local business listings to find nearby bearing suppliers.

2. Industrial Supply Stores: Many industrial supply stores carry a selection of bearings, including UCP bearings. These stores cater to a variety of industries and may have a dedicated section for bearings and power transmission components. Examples of such stores include Grainger, MSC Industrial Supply, and Fastenal. You can visit their physical locations or explore their online catalogs to find UCP bearings.

3. Online Marketplaces: Online marketplaces provide a convenient platform to browse and purchase UCP bearings from various sellers. Popular online marketplaces like Amazon, eBay, and Alibaba often have a wide selection of bearings available, including UCP bearings. When purchasing from online marketplaces, be sure to check the seller’s ratings and reviews to ensure reliability and product quality.

4. Bearing Manufacturers: Another option is to buy UCP bearings directly from bearing manufacturers. Many bearing manufacturers have their own websites or online stores where you can explore their product catalogs and make purchases. Some well-known bearing manufacturers include SKF, NSK, NTN, Timken, and FAG. Visiting their official websites can provide you with detailed information about their UCP bearing offerings and contact details for purchasing.

5. Specialized Bearings Retailers: There are specialized retailers that focus specifically on bearings and power transmission components. These retailers often have a wide range of bearing types and sizes, including UCP bearings. They may offer a more extensive selection and expertise in the field of bearings. Examples of specialized bearing retailers include Bearing Distributors Inc., Applied Industrial Technologies, and Motion Industries.

When purchasing UCP bearings, it’s important to consider factors such as product quality, availability, pricing, and customer support. Compare different suppliers or retailers to ensure you are getting the best value for your investment. Additionally, check if the supplier offers any warranties or guarantees on their products.

In summary, you can buy UCP bearings from local bearing suppliers, industrial supply stores, online marketplaces, bearing manufacturers, and specialized bearings retailers. Assess your specific requirements and preferences to choose the most suitable option for purchasing UCP bearings.

editor by CX 2024-05-16

China high quality Cast Iron Housing UCP Ucf UCT Ucfc UCFL Ucpa 204 205 206 207 208 209 210 211 212 213 214 215 216 217 218 220 Pillow Block Bearing Skfnsktimkeninakoyo bearing driver kit

Product Description

Product Description

Main Dimensions & Performance Dat

Pillow block bearing unit is a bearing unit that combines a rolling bearing with a bearing housing. Most pillow block bearings are made of spherical outer diameter and are installed with pillow block which have spherical inner holes. They have various structural forms, good versatility and interchangeability.

PILLOW BLOCK BEARINGS

Pillow block bearings, flange bearing units, bearing blocks, and take-up bearings units all consist of a housing with a bearing mounted in it they are available in a variety of materials, mounting configurations and various bearing features each mounted unit, including a mounted uc,sa,sb er series insert bearings.

Uses of Pillow Block Bearing

These units are extremely versatile and can be used in a variety of applications. They range from single bearing shafts to multiple bearing units.

1)Belt drive connecting motor and pump

2)A long shaft connecting the motor and the industrial gearbox

3)Conveyor roller

4)Rolling machine

5)Ventilation system

6)Paper machine

Detailed Photos

Pillow block bearing specifications:

| Unit No | Shaft Dia | Dimensions (mm) | Weight(kg) | |||||||||

| D | B | S | L | J | H | H1 | A | N | N1 | |||

| UCP201 | 12 | 40 | 27.4 | 11.5 | 125 | 96 | 30.2 | 57 | 36 | 13 | 19 | 0.6 |

| UCP202 | 15 | 40 | 27.4 | 11.5 | 125 | 96 | 30.2 | 57 | 36 | 13 | 19 | 0.7 |

| UCP203 | 17 | 40 | 27.4 | 11.5 | 125 | 96 | 30.2 | 57 | 36 | 13 | 19 | 0.7 |

| UCP204 | 20 | 47 | 31 | 12.7 | 127 | 95 | 33.3 | 65 | 38 | 13 | 19 | 0.75 |

| UCP205 | 25 | 52 | 34.1 | 14.3 | 140 | 105 | 36.5 | 71 | 38 | 13 | 19 | 0.8 |

| UCP206 | 30 | 62 | 38.1 | 15.9 | 165 | 121 | 42.9 | 83 | 48 | 17 | 23 | 1.3 |

| UCP207 | 35 | 72 | 42.9 | 17.5 | 167 | 127 | 46.7 | 93 | 48 | 17 | 23 | 1.6 |

| UCP208 | 40 | 80 | 42.9 | 19 | 184 | 137 | 49.2 | 100 | 54 | 17 | 23 | 1.9 |

| UCP209 | 45 | 85 | 49.2 | 19 | 190 | 146 | 54 | 106 | 54 | 17 | 23 | 2.2 |

| UCP210 | 50 | 90 | 51.6 | 19 | 206 | 159 | 57.2 | 114 | 60 | 20 | 26 | 2.6 |

| UCP211 | 55 | 100 | 55.6 | 22.2 | 219 | 171 | 63.5 | 126 | 60 | 20 | 26 | 3.3 |

| UCP212 | 60 | 110 | 65.1 | 25.4 | 241 | 184 | 69.8 | 138 | 70 | 20 | 26 | 4.6 |

| UCP213 | 65 | 120 | 65.1 | 25.4 | 265 | 203 | 76.2 | 151 | 70 | 25 | 31 | 5.9 |

| UCP214 | 70 | 125 | 74.6 | 30.2 | 266 | 210 | 79.4 | 157 | 72 | 25 | 31 | 6.6 |

| UCP215 | 75 | 130 | 77.8 | 33.3 | 275 | 217 | 82.6 | 163 | 74 | 25 | 31 | 7.4 |

| UCP216 | 80 | 140 | 82.6 | 33.3 | 292 | 232 | 88.9 | 175 | 78 | 25 | 31 | 9.0 |

| UCP217 | 85 | 150 | 85.7 | 34.1 | 310 | 247 | 95.2 | 187 | 83 | 25 | 31 | 11 |

| UCP218 | 90 | 160 | 96 | 39.7 | 327 | 262 | 101.6 | 200 | 88 | 27 | 33 | 13 |

| UCP220 | 100 | 180 | 108 | 42 | 380 | 308 | 115 | 225 | 95 | 30 | 38 | 16 |

| UCP305 | 25 | 62 | 38 | 15 | 175 | 132 | 45 | 85 | 45 | 17 | 20 | 1.4 |

| UCP306 | 30 | 72 | 43 | 17 | 180 | 140 | 50 | 95 | 50 | 17 | 20 | 1.8 |

| UCP307 | 35 | 80 | 48 | 19 | 210 | 160 | 56 | 106 | 56 | 17 | 25 | 2.8 |

| UCP308 | 40 | 90 | 52 | 19 | 220 | 170 | 60 | 116 | 60 | 17 | 27 | 3.0 |

| UCP309 | 45 | 100 | 57 | 22 | 245 | 190 | 67 | 129 | 67 | 20 | 30 | 4.1 |

| UCP310 | 50 | 110 | 61 | 22 | 275 | 212 | 75 | 143 | 75 | 20 | 35 | 5.8 |

| UCP311 | 55 | 120 | 66 | 25 | 310 | 236 | 80 | 154 | 80 | 20 | 38 | 7.4 |

| UCP312 | 60 | 130 | 71 | 26 | 330 | 250 | 85 | 165 | 85 | 25 | 38 | 9.4 |

| UCP313 | 65 | 140 | 75 | 30 | 340 | 260 | 90 | 176 | 90 | 25 | 38 | 10.0 |

| UCP314 | 70 | 150 | 78 | 33 | 360 | 280 | 95 | 187 | 90 | 27 | 40 | 12.0 |

| UCP315 | 75 | 160 | 82 | 33 | 380 | 290 | 100 | 198 | 100 | 27 | 40 | 14.0 |

| UCP316 | 80 | 170 | 86 | 34 | 400 | 300 | 106 | 210 | 110 | 27 | 40 | 18.0 |

| UCP317 | 85 | 180 | 96 | 40 | 420 | 320 | 112 | 220 | 110 | 33 | 45 | 20.0 |

| UCP318 | 90 | 190 | 96 | 40 | 430 | 330 | 118 | 235 | 110 | 33 | 45 | 24.0 |

| UCP319 | 95 | 200 | 103 | 41 | 470 | 360 | 125 | 250 | 120 | 36 | 50 | 29.0 |

| UCP320 | 100 | 215 | 108 | 42 | 490 | 380 | 140 | 275 | 120 | 36 | 50 | 35.0 |

| UCP321 | 105 | 225 | 112 | 44 | 490 | 380 | 140 | 280 | 120 | 36 | 50 | 35.0 |

| UCP322 | 110 | 2240 | 117 | 46 | 520 | 400 | 150 | 300 | 140 | 40 | 55 | 45.0 |

| UCP324 | 120 | 260 | 126 | 51 | 570 | 450 | 160 | 320 | 140 | 40 | 55 | 55.0 |

| UCP326 | 130 | 280 | 135 | 54 | 600 | 480 | 180 | 355 | 140 | 40 | 55 | 72.0 |

| UCP328 | 140 | 300 | 145 | 59 | 620 | 500 | 200 | 390 | 140 | 40 | 55 | 89.0 |

Packaging & Shipping

Packing:

Please contact us for more pictures of different packing.

|

Universal Packing |

Without any logo on bearings or packing. |

|

JDZ Packing |

With our brand JDZ on bearings and packing. |

|

Customized Packing |

Depends on buyer’s requirements. |

|

Original Brand Packing |

Bearing and packing are both original. Please contact us for pictures. |

QUALITY ASSURANCE

100% Quality inspection to ensure the bearings are with good quality before shipping.

Company Profile

ZheJiang CZPT Precision Bearing Co.,Ltd. was founded by ZheJiang Defa Bearing Co.,Ltd, factory is located in ZheJiang province, China.

We are a bearing manufacturer integrating the research, development and sales of bearings, with a floor area of 18,000 square meters and a plant area of 8,800 square meters. Equipped with modern production equipment and advanced detection instruments.

We can provide all types bearings and OEM service according to customers’ requirements.

Our products are widely used in the automobile, agricultural, textile production, mining, printing and packing industries, in addition to various applications at airports, in air-conditioning systems, conveying devices, ships ad so on. Our products are being exported to more than 50 countries and regions overseas including Singapore, Thailand, Iran, Turkey, Poland, Italy, England, France, Russia, Germany, the United States, Australia, Argentina, Brazil as well as other countries and regions all over the world.

We are a trusted and reliable bearing supplier, choose us to be your good partner!

Quality Inspection.

Our Advantages:

1. Professional production team with advanced production equipment and testing instruments.

2. Many years of export experience can provide customers with better service and problem-solving capabilities.

3. Customers all over the world enable us to better understand the market and provide customers with suitable bearings.

4. Sincerity, cooperation, mutual and provide good quality bearings for clients are the development idea of our company

5. Quick delivery, shipping goods on time. Save more time and cost for all customers.

FAQ

1. Q: Are you trading company or manufacturer ?

A: We have our own factory , our type is factory + trade.

2. Q: Could you accept OEM and customize?

A: Yes, we can customize products according to your sample or drawing.

3. Q: How long is your delivery time?

A: If stock, within 7 days to ship or based on your order quantity.

4. Q: Could you supply sample for free?

A: Yes, we can offer the sample for free,do you mind to buy a “ticket” for her?

More details, please contact with us. Thanks for your time!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Ball Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How to identify the size and specifications of a UCP bearing?

Identifying the size and specifications of a UCP bearing, also known as a pillow block bearing, requires examining various parameters and markings on the bearing itself or referring to manufacturer documentation. Here’s a detailed explanation of how to identify the size and specifications of a UCP bearing:

1. Bearing Markings: Start by inspecting the bearing for any markings or labels that provide information about its size, type, and specifications. Common markings may include the manufacturer’s logo or name, bearing model or part number, and any relevant standards or certifications. These markings can help identify the specific UCP bearing and provide a starting point for gathering further information.

2. Dimensions: Determine the dimensions of the UCP bearing, including the bore diameter (inner diameter), outer diameter, and overall width. These dimensions are typically specified in millimeters (mm) or inches (in). Measuring the bearing with calipers or using a ruler can help determine its size. Alternatively, the dimensions can be obtained from manufacturer catalogs, datasheets, or online resources.

3. Pillow Block Type: UCP bearings come in various pillow block types, such as UCP200 series or UCP300 series, which indicate different design variations and size ranges. The pillow block type is often indicated in the bearing model or part number. Identifying the specific series or type helps in selecting compatible components and determining the bearing’s load capacity and performance characteristics.

4. Load Capacity and Ratings: The load capacity and ratings of a UCP bearing are crucial specifications to consider for proper application. They indicate the maximum allowable radial and axial loads that the bearing can withstand. Load capacity information is typically provided by the manufacturer and can be found in bearing catalogs or technical documentation. It is important to ensure that the bearing’s load capacity meets the requirements of the application to prevent premature failure.

5. Lubrication: Determine the lubrication requirements of the UCP bearing. This includes identifying the recommended lubricant type, such as grease or oil, as well as the appropriate amount and frequency of lubrication. Lubrication information is often provided by the manufacturer and can be found in bearing documentation or technical specifications.

6. Sealing and Shielding: Check if the UCP bearing has any seals or shields to protect against contamination and retain lubrication. The type of seal or shield used can impact the bearing’s performance in different environments. Common seal types include rubber seals, metal shields, or labyrinth seals. The sealing arrangement may be indicated in the bearing model or part number, or it can be obtained from manufacturer documentation.

7. Manufacturer Documentation: Consult the manufacturer’s documentation, such as catalogs, datasheets, or technical manuals, for detailed information about the UCP bearing’s size, specifications, and performance characteristics. Manufacturer resources provide comprehensive information and ensure accurate identification of the bearing.

It’s important to note that the identification process may vary depending on the manufacturer and specific bearing model. If you encounter difficulties or require precise information, contacting the bearing manufacturer, distributor, or a knowledgeable expert in the field can provide further guidance and assistance in identifying the size and specifications of a UCP bearing.

Taking accurate measurements, referring to bearing markings, and utilizing manufacturer resources are key steps in correctly identifying and selecting the appropriate UCP bearing for a given application.

How to replace a UCP bearing?

Replacing a UCP bearing, also known as a pillow block bearing, requires careful handling and following specific steps to ensure a successful replacement. Here’s a detailed explanation of the process to replace a UCP bearing:

- Gather the necessary tools: Before starting the replacement, gather the tools you will need, including a wrench or socket set, a puller or press (if needed), cleaning materials, and the replacement UCP bearing.

- Prepare the work area: Ensure that the work area is clean and well-lit. If the machinery is still operational, shut it down and follow proper lockout/tagout procedures to prevent accidental startup during the replacement process.

- Remove any obstructions: If there are any covers, guards, or other components obstructing access to the UCP bearing, remove them carefully to expose the bearing housing.

- Loosen the locking mechanism: Use a wrench or socket set to loosen the locking mechanism that secures the UCP bearing in place. This could be a set screw, collar, or other locking device. Follow the manufacturer’s instructions to identify and release the locking mechanism.

- Remove the UCP bearing: Once the locking mechanism is loosened, the UCP bearing can be removed from the housing. Apply gentle force if necessary, but avoid excessive impacts or prying that may damage the bearing or the housing.

- Clean the housing: Thoroughly clean the housing to remove any dirt, debris, or old lubricant. Use appropriate cleaning materials and ensure that the housing is dry before installing the new UCP bearing.

- Inspect and prepare the replacement bearing: Before installing the new UCP bearing, inspect it for any signs of damage or defects. Ensure that the bore and outer surfaces are clean and free from any contaminants. If necessary, apply a suitable lubricant to the bearing per the manufacturer’s recommendations.

- Install the new UCP bearing: Carefully position the new UCP bearing into the housing, aligning the bore with the shaft. Apply even pressure to press the bearing into place, ensuring it is seated securely. Follow the manufacturer’s instructions for any specific installation requirements, such as tightening torque for the locking mechanism.

- Secure the locking mechanism: Once the new UCP bearing is installed, tighten the locking mechanism to secure it in place. Again, follow the manufacturer’s instructions for the specific tightening procedure and torque value.

- Reinstall any obstructions: Put back any covers, guards, or components that were removed earlier to restore the machinery to its original configuration.

- Test and verify: After the replacement is complete, test the machinery to ensure proper operation of the new UCP bearing. Monitor for any unusual noise, vibration, or other issues that may indicate incorrect installation or other problems.

It’s important to note that the specific steps for replacing a UCP bearing may vary depending on the machinery and the manufacturer’s recommendations. Always refer to the manufacturer’s documentation, maintenance manuals, or technical support for the most accurate and detailed instructions for your specific UCP bearing and machinery.

Additionally, if you are unsure or uncomfortable with performing the replacement yourself, it’s recommended to seek the assistance of a qualified technician or maintenance professional to ensure the proper installation and functioning of the UCP bearing.

What are the dimensions of standard UCP bearings?

Standard UCP bearings, also known as pillow block bearings, come in various sizes and configurations to accommodate different shaft diameters. The dimensions of UCP bearings are typically specified by the bore diameter, overall length, width, and mounting hole spacing. Here’s a detailed explanation of the dimensions commonly associated with standard UCP bearings:

- Bore Diameter: The bore diameter refers to the inner diameter of the bearing, which determines the size of the shaft that can be accommodated. Standard UCP bearings are available in a range of bore diameters, such as 20 mm, 25 mm, 30 mm, 35 mm, 40 mm, 45 mm, 50 mm, and larger. The specific bore diameter required for your application will depend on the size of the shaft you are working with.

- Overall Length: The overall length of a UCP bearing refers to the distance between the outermost points of the bearing’s housing. It includes the length of the bearing itself and any additional extensions or flanges that may be present. The overall length can vary depending on the specific design and manufacturer, but it is typically standardized within certain size ranges.

- Width: The width of a UCP bearing refers to the measurement from one side of the bearing to the opposite side. It represents the thickness of the bearing’s housing. Similar to the overall length, the width can vary depending on the specific design and manufacturer, but it is often standardized within certain size ranges.

- Mounting Hole Spacing: UCP bearings have mounting holes on their base or flange, which are used to secure the bearing to a mounting surface. The mounting hole spacing refers to the distance between the centers of the mounting holes. This dimension is crucial for proper installation and compatibility with the corresponding mounting arrangement.

It’s important to note that the dimensions of UCP bearings can vary between manufacturers and series. Therefore, it is essential to consult the specific manufacturer’s documentation or product specifications to obtain accurate and detailed information about the dimensions of a particular UCP bearing model.

In summary, the dimensions of standard UCP bearings include the bore diameter, overall length, width, and mounting hole spacing. These dimensions can vary depending on the specific design and manufacturer. Refer to the manufacturer’s documentation for precise information on the dimensions of a particular UCP bearing model.

editor by CX 2024-05-16

China supplier Pb251urx3/4 Pillow Block Mounted Bearing bearing assembly

Product Description

Product Description:

Pillow block bearings is actually a variant of deep groove ball bearings, is characterized by its outer diameter surface of the sphere, you can play with the corresponding inner concave spherical bearing self-aligning effct.

Pillow block bearing mainly used to bearadical load mainly radial and axial joint load, generally should not alone bear the axial load ,such a bearing inner and outer ring can be installed separately.

Pillow block bearing models

| model number | d(mm) | D(mm) | b(mm) |

| UCP201 | 12 | 127 | 62 |

| UCP202 | 15 | 127 | 62 |

| UCP203 | 17 | 127 | 62 |

| UCP204 | 20 | 127 | 62 |

| UCP205 | 25 | 140 | 71 |

| UCP206 | 30 | 165 | 83 |

| UCP207 | 35 | 167 | 93 |

| UCP208 | 40 | 184 | 100 |

| UCP209 | 45 | 190 | 106 |

| UCP210 | 50 | 206 | 114 |

| UCP211 | 55 | 219 | 126 |

| UCP212 | 60 | 241 | 138 |

| UCP213 | 65 | 265 | 151 |

| UCP214 | 70 | 266 | 157 |

| UCP215 | 75 | 275 | 163 |

| UCP216 | 80 | 292 | 175 |

| UCP217 | 85 | 310 | 187 |

| UCP218 | 90 | 327 | 200 |

| UCP220 | 100 | 380 | 225 |

| UCP306 | 30 | 180 | 85 |

| UCP307 | 35 | 210 | 106 |

| UCP308 | 40 | 220 | 116 |

| UCP309 | 45 | 245 | 129 |

| UCP310 | 50 | 275 | 143 |

| UCP311 | 55 | 310 | 154 |

| UCP312 | 60 | 330 | 165 |

Company Information:

ZheJiang XSY Bearing Co.,Ltd. is a leading and professional manufacturer of bearings, based on R & D, producing and sales of precision bearings with more than 25 years experience. Our own bearing brand is “ZGXSY”, including Tapered Roller Bearing, Deep Groove Ball Bearing, Thrust Ball Bearing, Thrust Roller Bearing, Spherical Roller Bearing, Angular Contact Ball Bearing, Self-aligning Ball Bearing and Cylindrical Roller Bearing. The inside diameter is from 5mm to 1000mm with CE ISO TUV certificate, besides we also offer the Bearings Accessories, such as Bearing Housings, Adapter Sleeve, Withdrawal Sleeve, Lock nut, Cage, Roller an Ball.

Application:

Package :

Contact:

xsybearing

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 45° |

|---|---|

| Aligning: | Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How to identify the size and specifications of a UCP bearing?

Identifying the size and specifications of a UCP bearing, also known as a pillow block bearing, requires examining various parameters and markings on the bearing itself or referring to manufacturer documentation. Here’s a detailed explanation of how to identify the size and specifications of a UCP bearing:

1. Bearing Markings: Start by inspecting the bearing for any markings or labels that provide information about its size, type, and specifications. Common markings may include the manufacturer’s logo or name, bearing model or part number, and any relevant standards or certifications. These markings can help identify the specific UCP bearing and provide a starting point for gathering further information.

2. Dimensions: Determine the dimensions of the UCP bearing, including the bore diameter (inner diameter), outer diameter, and overall width. These dimensions are typically specified in millimeters (mm) or inches (in). Measuring the bearing with calipers or using a ruler can help determine its size. Alternatively, the dimensions can be obtained from manufacturer catalogs, datasheets, or online resources.

3. Pillow Block Type: UCP bearings come in various pillow block types, such as UCP200 series or UCP300 series, which indicate different design variations and size ranges. The pillow block type is often indicated in the bearing model or part number. Identifying the specific series or type helps in selecting compatible components and determining the bearing’s load capacity and performance characteristics.

4. Load Capacity and Ratings: The load capacity and ratings of a UCP bearing are crucial specifications to consider for proper application. They indicate the maximum allowable radial and axial loads that the bearing can withstand. Load capacity information is typically provided by the manufacturer and can be found in bearing catalogs or technical documentation. It is important to ensure that the bearing’s load capacity meets the requirements of the application to prevent premature failure.

5. Lubrication: Determine the lubrication requirements of the UCP bearing. This includes identifying the recommended lubricant type, such as grease or oil, as well as the appropriate amount and frequency of lubrication. Lubrication information is often provided by the manufacturer and can be found in bearing documentation or technical specifications.

6. Sealing and Shielding: Check if the UCP bearing has any seals or shields to protect against contamination and retain lubrication. The type of seal or shield used can impact the bearing’s performance in different environments. Common seal types include rubber seals, metal shields, or labyrinth seals. The sealing arrangement may be indicated in the bearing model or part number, or it can be obtained from manufacturer documentation.

7. Manufacturer Documentation: Consult the manufacturer’s documentation, such as catalogs, datasheets, or technical manuals, for detailed information about the UCP bearing’s size, specifications, and performance characteristics. Manufacturer resources provide comprehensive information and ensure accurate identification of the bearing.

It’s important to note that the identification process may vary depending on the manufacturer and specific bearing model. If you encounter difficulties or require precise information, contacting the bearing manufacturer, distributor, or a knowledgeable expert in the field can provide further guidance and assistance in identifying the size and specifications of a UCP bearing.

Taking accurate measurements, referring to bearing markings, and utilizing manufacturer resources are key steps in correctly identifying and selecting the appropriate UCP bearing for a given application.

How to choose the right UCP bearing for my machinery?

Choosing the right UCP bearing, also known as a pillow block bearing, for your machinery is crucial to ensure optimal performance, reliability, and longevity. Here’s a detailed explanation of the factors to consider when selecting a UCP bearing:

- Load Requirements: Evaluate the load requirements of your machinery, including the magnitude and direction of the loads. Consider factors such as radial loads, axial loads, and moment loads. Ensure that the UCP bearing you choose has a load capacity that is suitable for the anticipated loads in your application.

- Shaft Diameter: Determine the shaft diameter of your machinery and select a UCP bearing with a corresponding bore size. The bore size of the UCP bearing should match the shaft diameter to ensure proper fit and alignment. It’s important to measure the shaft accurately and consider any potential expansion or misalignment during operation.

- Operating Conditions: Assess the operating conditions of your machinery, including factors such as speed, temperature, and environmental conditions. Choose a UCP bearing that is designed to withstand the anticipated operating conditions. Consider factors like maximum speed rating, temperature range, lubrication requirements, and resistance to contaminants or moisture.

- Sealing and Protection: Depending on the application requirements, consider whether additional sealing or protection is necessary for the UCP bearing. Seals or shields can help prevent the ingress of dirt, dust, or contaminants, prolonging the bearing’s life and reducing maintenance needs. Choose a UCP bearing with appropriate sealing options, such as rubber seals or metal shields, based on the specific environmental conditions.

- Alignment Capability: Evaluate the alignment capabilities of the UCP bearing. Some UCP bearings have self-aligning features that can compensate for minor shaft misalignment. If your machinery is prone to misalignment or has flexible shafts, consider choosing a UCP bearing with self-aligning properties to minimize excessive loads and premature wear.

- Manufacturer and Quality: Select UCP bearings from reputable manufacturers known for their quality and reliability. Consider manufacturers with a strong track record in bearing production and a wide range of product offerings. Research customer reviews, consult with industry experts, and consider the manufacturer’s reputation for producing durable and high-performance UCP bearings.

By considering these factors and choosing a UCP bearing that aligns with your machinery’s specific requirements, you can ensure optimal performance and minimize the risk of premature failures or downtime. It’s recommended to consult with bearing specialists, engineers, or the manufacturer’s technical support team for additional guidance and assistance in selecting the most suitable UCP bearing for your machinery.

Remember that the specific requirements for UCP bearings may vary depending on the application, industry, and machinery specifications. Always refer to the manufacturer’s documentation, specifications, and guidelines for the most accurate and detailed information.

How is a UCP bearing different from other types of bearings?

A UCP bearing, also known as a pillow block bearing, has distinct characteristics that set it apart from other types of bearings. While bearings serve the common purpose of facilitating motion and reducing friction, UCP bearings have specific design features that make them unique. Here’s a detailed explanation:

1. Pillow Block Design: One key difference is the design of the housing. UCP bearings have a pillow block design, which refers to the shape of the housing. The housing is typically a solid, one-piece structure shaped like a pillow or block, with a flat base and mounting holes. This design allows for easy installation and mounting on a support structure or machine.

2. Mounted Bearing: UCP bearings are mounted bearings, meaning they are preassembled units that combine a bearing unit with a housing. The bearing unit consists of a rolling element bearing, such as a ball bearing or a roller bearing, which enables smooth and low-friction motion. The housing provides support and protection for the bearing unit.

3. Support Structure: UCP bearings are commonly used in applications where a shaft needs to be supported and allowed to rotate or move linearly. The housing of a UCP bearing serves as a support structure for the bearing unit and provides a stable platform for the shaft to operate.

4. Easy Installation: UCP bearings are designed for easy installation. The housing’s flat base and pre-drilled mounting holes allow for straightforward attachment to a support structure or machine. This ease of installation simplifies the setup process and reduces downtime.

5. Application Versatility: UCP bearings are widely used in various applications across different industries. They are commonly found in conveyor systems, agricultural machinery, industrial equipment, HVAC systems, and more. The versatility of UCP bearings makes them suitable for a range of motion control and power transmission applications.

6. Specific Load Capacity: UCP bearings have specific load capacity ratings depending on the type and size of the bearing unit used within the UCP assembly. These bearings can support both radial and axial loads, allowing them to accommodate different load requirements in various applications.

7. Protection and Contamination Resistance: The housing of a UCP bearing provides protection to the bearing unit against contaminants, moisture, and other external elements. This helps extend the bearing’s service life and maintain its performance in challenging operating conditions.